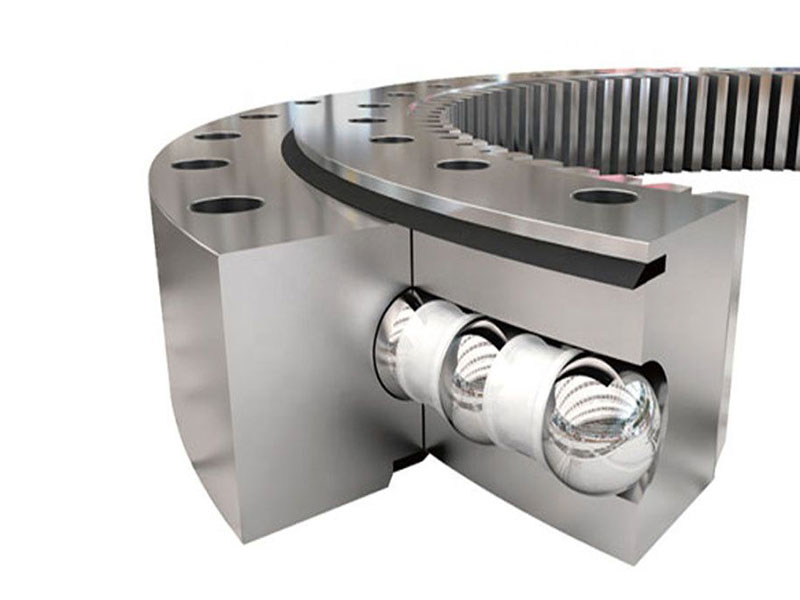

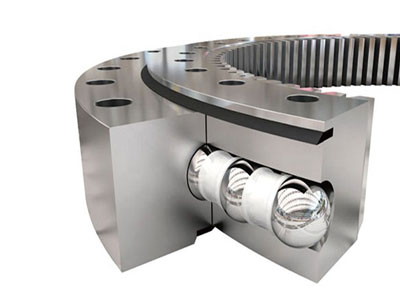

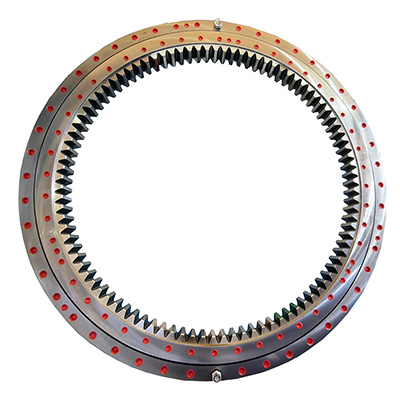

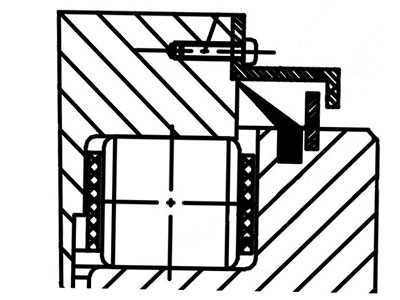

Four-point Contact Ball Bearing

Four-point Contact Ball Bearing comprises an inner ring and an outer ring. Featuring compact design, light weight and four-point contact ball configuration, this slewing ring is designed with excellent dynamic load capacity to handle axial, radial and tilting moment loads.

Four-point contact ball slewing rings are particularly versatile and are widely used in cranes, lifting equipment and other engineering machinery.

- Outer diameter: 602mm~4726mm

- Ball diameter: 30mm~75mm

- Rated load: 129kN~3410kN

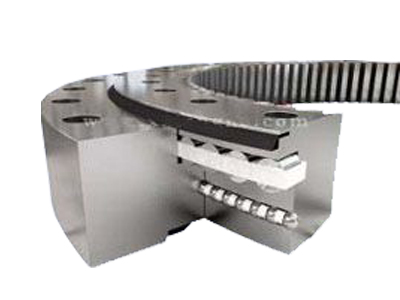

Four-point contact ball bearing is comprised of an outer ring and an inner ring in integral structure or split structure. The two split rings of bearings in split structure are bolted together before delivery. Usually cages or spacers can be found in four-point contact ball bearings. In addition, bearings in full-filled ball structure is used only for large loads, thereby the full-filled ball structure bearings features good loading capacity and larger friction, the latter may result in scratches on the contact balls.

- Range of external diameter: 100 mm to 15000 mm

- Ring material: 42CrMo / 50Mn/ C45

- Ball/roller material: GCr15

- Cage material: steel 20 or ZL102 cast aluminum alloy

- Spacer material: nylon 6 / nylon 66

- Quenching hardness of raceway: HRC55-62

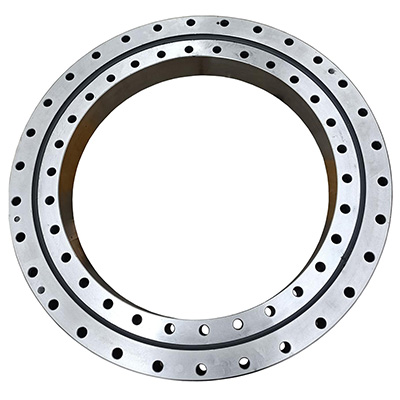

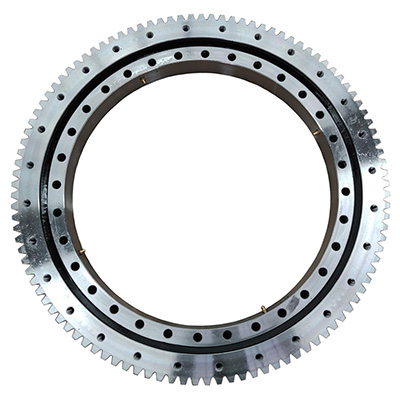

- Tooth type: no gear, internal gear, external gear

- Excavator

- Crane

- Rotary conveyor

- Port machinery

- Wind power generation

- Amusement facilities

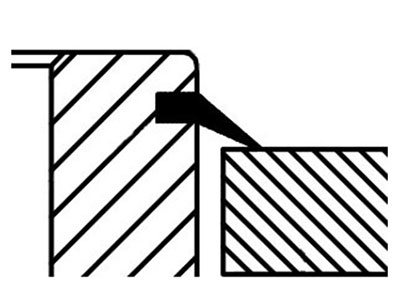

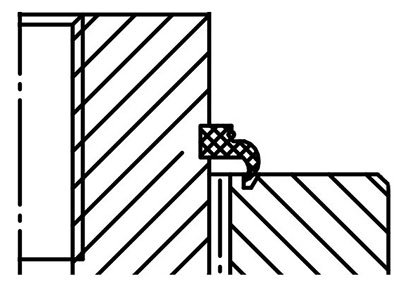

The sealing of the slewing bearing, on the one hand, is to prevent the leakage of filled grease, on the other hand, is to prevent the outside dust, impurities and moisture from invading into the exterior of the bearing and affecting its work. The sealing ring of LYJW slewing bearing is made of nitrile rubber material, which is resistant to high temperature and corrosion.

The raceways of slewing ring bearing are quenched on the surface. Its quenching hardness is set at HRC55-62, ensuring its effective hardening depth.

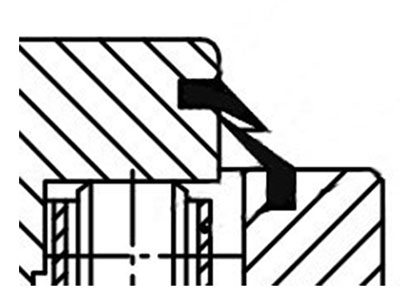

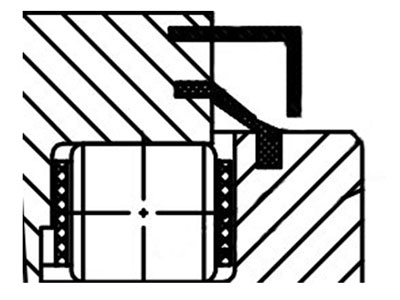

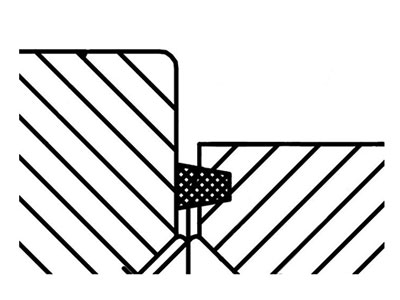

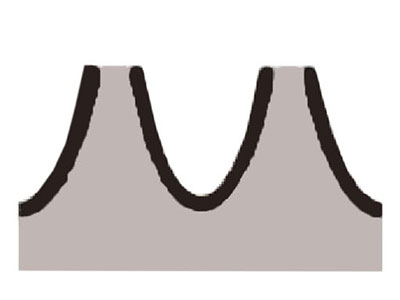

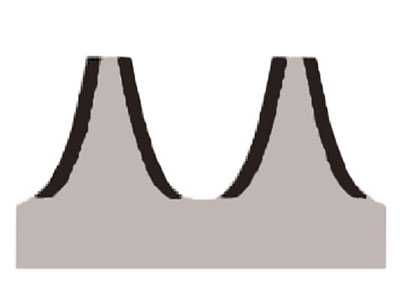

Due to the need to transmit force, slewing bearings usually have teeth on one of the rings. The toothing is generally normalized or quenched and tempered. Depending on the application, the gears can also be full-tooth hardened or single-tooth inductively hardened. Single tooth inductively hardening can be divided into full tooth hardening and tooth foot (flanks and base) hardening.

Full tooth hardening

Full tooth hardening

Tooth flanks and base hardening

Tooth flanks and base hardening

Tooth flanks Hardening

Tooth flanks Hardening

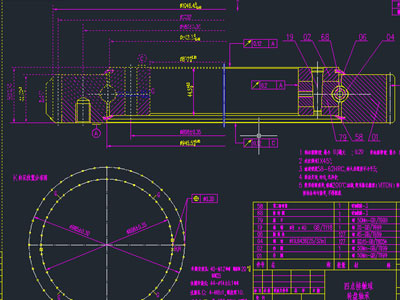

Custom Bearings

Our dedicated team is on hand to provide help and expertise throughout the process. Whether you are ordering from our standard range of products or you want a tailored solution for your current project, they are ready to help you every step of the way.

MoreTags

LYJW is a professional manufacturer of slewing bearings and we can design and manufacture slew ring bearings, precision bearings, slew drives and custom bearings for construction, engineering, mining, marine, chemical, military, wind turbine, medical equipment, and many other industries.

By virtue of expertise team, advanced manufacturing technologies and strict quality management system, LYJW takes the lead in the R&D of slewing bearings, which are designed with reasonable construction, light weight, good load carrying capacity and high versatility. The bearings’ diameters range from 200 to 15000mm and the accuracy covers PO, P6 and P5 class. Now, we can manufacture CCS, ABS, BV, GL and other certified bearings.

We adhere to the business principle of “Quality and Integrity” and we’ll keep providing outstanding bearings and superior services to serve global customer.