- Can the bearing be customized?

-

Yes. We can customize the bearing. Please tell us the external diameter, internal diameter and other conditions, and then we will recommend a suitable model for you.

- I have a bearing from another manufacturer. Can I get an equivalent slewing bearing?

-

Yes. LYJW will produce what you need according to the drawing.

- Are your bearings in stock? I'm in a hurry to use it.

-

We have bearings of common types in stock. You can tell us the bearing model or its size, we will check the inventory.

- I need bearings for a new project, but I don't know which kind is suitable. Can you help me?

-

LYJW’s team of application engineers will work with you through every step of the way and choose the bearing most suited to your application.

- Will it take longer for a customized bearing order?

-

Our average delivery time for bearings is 5-7 weeks. Expedited delivery will come in approximately 2-3 weeks.

- Can you match a pinion for our slewing bearing with external gears?

-

Yes. LYJW can design a suitable pinion for you according to the parameters of your slewing bearing.

- Do LYJW bearings come with a warranty?

-

Yes. A one-year warranty is offered to all customers. Longer warranties are available upon request and may require additional costs.

- I'm not going to use all of my bearings at once. I’m worried that if they will rust for being in the inventory for a while.

-

No. All our bearings have a protective oil film on them with kraft paper and a plastic overwrap outside to prevent moisture.

Not finding the answer you are looking for?

If you are looking for specific information and not finding it in the FAQ don’t hesitate to

-

Services

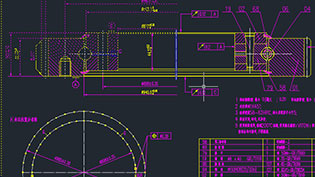

MoreWe offer both standard and custom bearings tailored to our customers’ specific requirements. After a thorough examination of the bearing condition, size, bearing tooth parameters and any other special processes prescribed by the customer, we will then recommend the most suitable model. To ensure the customer's satisfaction, we also provide detailed diagrams, three-dimensional drawings, and load curves to confirm.

-

Custom Bearings

MoreOur dedicated team is on hand to provide help and expertise throughout the process. Whether you are ordering from our standard range of products or you want a tailored solution for your current project, they are ready to help you every step of the way.

-

Manufacturing Process

MoreAfter rough turning, the workpiece is detected by an ultrasonic flaw detector to examine cracks or other flaws and ensure the bearing’s stable quality and normal service life. Quenching and tempering can be conducted according to the requirements, to improve the strength and fatigue resistance of the material.

-

Quality Certificates

MoreTo ensure consistent quality control, we have applied a series of specific and strict measures across all areas of our company. As a high-tech enterprise, our products have passed ISO9001-2000 quality system certification, CCS, ABS, BV, GL and other certifications, and have obtained a number of patent certificates.