Custom Bearings

Customized Slewing Bearing, Slew Drive, Precision Bearings for Your Application

Our dedicated team is on hand to provide help and expertise throughout the process. Whether you are ordering from our standard range of products or you want a tailored solution for your current project, they are ready to help you every step of the way.

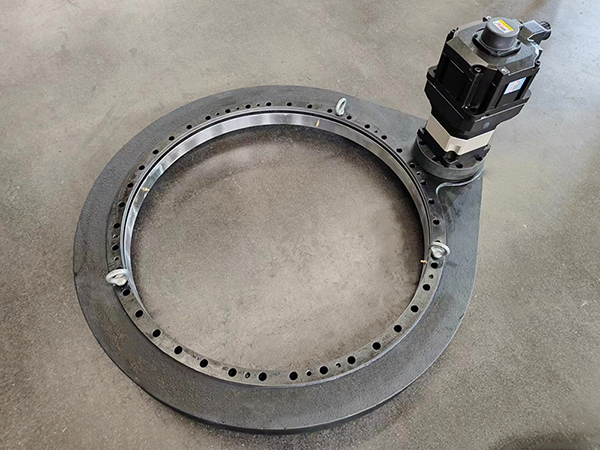

In addition, we will determine and deliver the drive components (pinion, pinion shaft, etc.) as well as the connecting elements (e.g., special bolts) for your adjacent structure on request.

Customization range

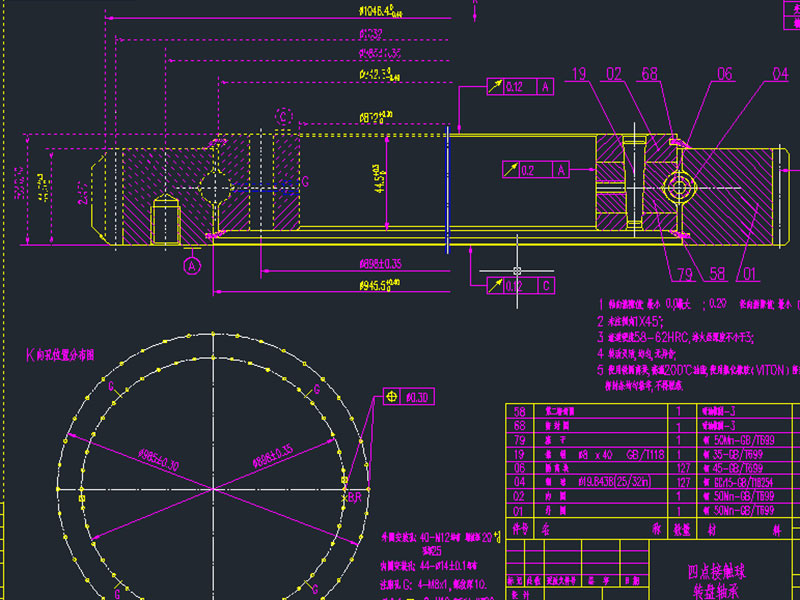

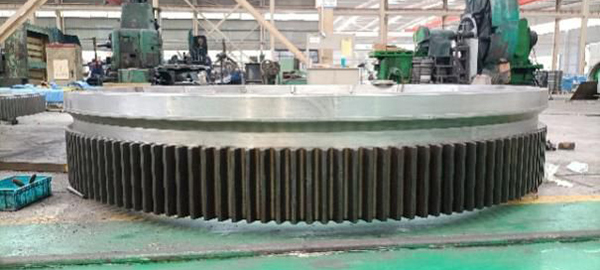

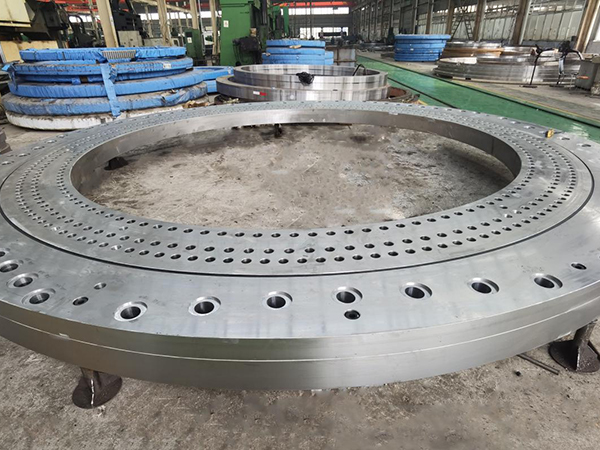

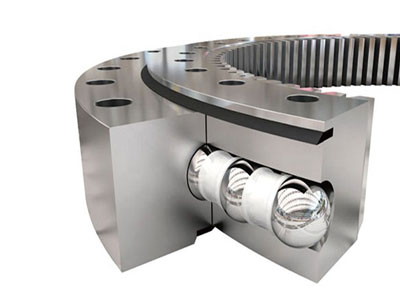

Product type: rotary table bearing, precision bearing, slew drive, ultra-large bearing

Product size: 100mm-15000mm

-

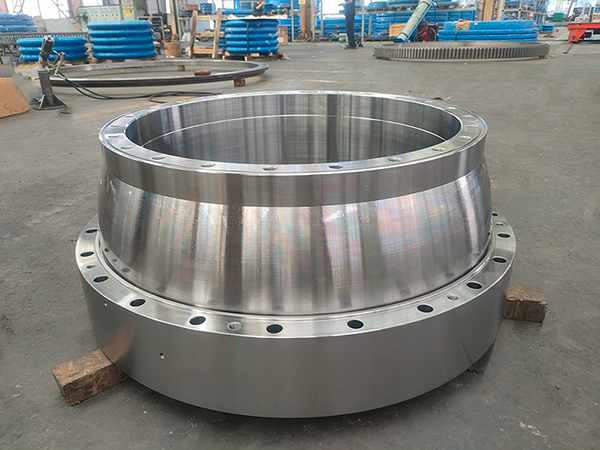

Bearing ring

LYJW bearing rings are made of high quality 42CrMo/50Mn and the raceway surface is quenched. We can provide rings of other materials according to customer’s specific requirements. -

Rustproof surface coating

Coating on the bearing surface can lubricate and protect the bearing. We provide yellow chromate surface coating film which can prevent rust for 5 to 10 years. Other rustproof surface coatings are also available upon request. -

Rollers

Quenched GCr15 or GCrl5SiMn steel rollers feature high abrasion resistance and long service life. -

Bearing cage

There are different types of bearing cages used for slewing bearings, such as integral cage, segmented cage or spaced cage. The integral cage or segmented cage is made of no. 20 steel or ZLl 02 cast aluminum alloy. The spaced cage is made of polyamide 1010 resin, ZLl 02 cast aluminum alloy, QALL0-3-1.5 aluminum bronze or GRPA66-25 nylon. Different cages can also be selected according to the specific application conditions provided by users. -

Lubricating grease: a proper lubricating grease is selected based on the load, temperature, vibration, and environmental conditions of bearing and below characteristics are necessary:

- Good waterproofness and resistance against high or low working temperature

- Upper limit of the normal working temperature is at least 20℃ higher than that of the slewing bearing.

- Excellent resistance against abrasion and extrusion.

- Appropriate consistency (for centralized lubricating system).

The lubricating grease commonly used in slewing bearings includes calcium-based grease, lithium-based grease, aluminum-based grease, etc., which can be chosen according to specific needs.

Customized samples

Tags

LYJW is a professional manufacturer of slewing bearings and we can design and manufacture slew ring bearings, precision bearings, slew drives and custom bearings for construction, engineering, mining, marine, chemical, military, wind turbine, medical equipment, and many other industries.

By virtue of expertise team, advanced manufacturing technologies and strict quality management system, LYJW takes the lead in the R&D of slewing bearings, which are designed with reasonable construction, light weight, good load carrying capacity and high versatility. The bearings’ diameters range from 200 to 15000mm and the accuracy covers PO, P6 and P5 class. Now, we can manufacture CCS, ABS, BV, GL and other certified bearings.

We adhere to the business principle of “Quality and Integrity” and we’ll keep providing outstanding bearings and superior services to serve global customer.