-

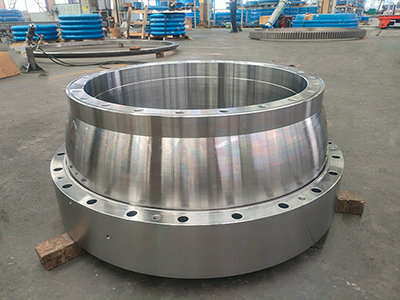

- Split gear ring with 11,304mm outer diameter exported to South Africa

-

External Diameter: 11,304 mm

Learn More

Weight: 9,200 kg

Material: 42CrMo castings

Application: Mining equipment

Country: South Africa

-

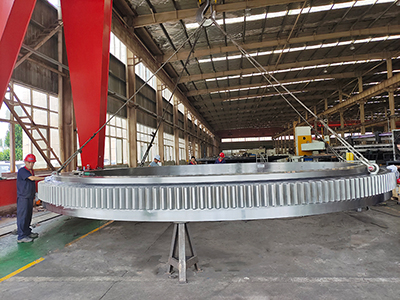

- Customized 4768mm split slewing bearing for South Korean client

-

Outer Diameter: 4768mm

Learn More

Weight: 4920kg

Material: 42CrMo

Application: Pile foundation machinery

Country: South Korea

-

- Precision 1200mm external gear slewing drive for radar systems

-

Outer Diameter: 1200mm

Learn More

Weight: 220kg

Material: 42CrMo

Application: Radar systems

-

- Spherical plain bearings were successfully developed and exported

-

Model: QGJ-0600

Learn More

Outer Diameter: 1020mm

Weight: 780kg

Application: transmission of tunnel boring machines

-

- Special turntable bearing for the harbor gantry crane was successfully delivered

-

Model: 132.85.7200.03

Learn More

Outer Diameter: 7897mm

Weight: 47000kg

Application: 1000t harbor gantry cranes

-

- Precision slewing ring bearing with an outer diameter of 5100mm was exported to the USA

-

Country: United States

Learn More

Product: High precision slewing ring bearing 010.50.4724

Outer Diameter: 5100mm

Application: Medical machinery

Challenge: Maximum radial runout ≤0.05 mm

-

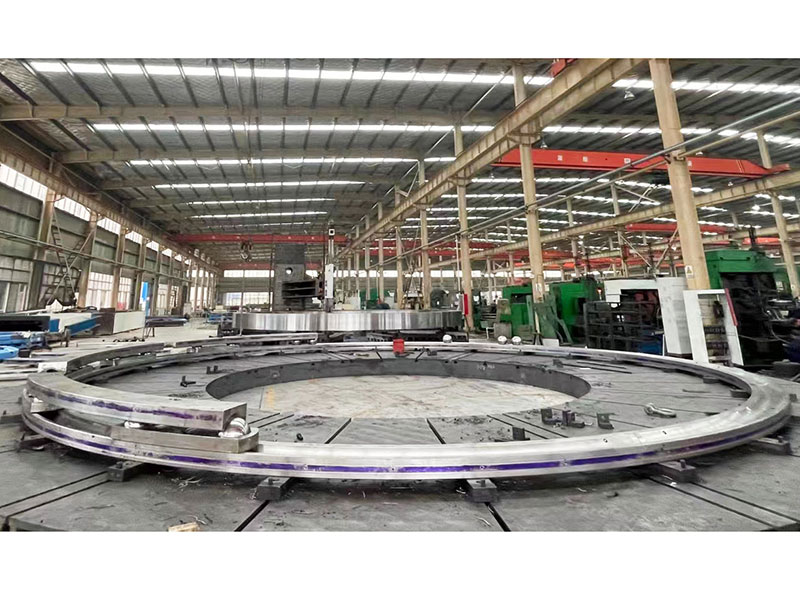

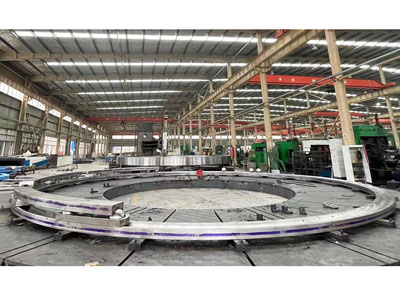

- A set of slewing ring with an outer diameter of 6100mm was exported to Southeast Asia

-

Country: Southeast Asia

Learn More

Product: Slewing ring

Outer diameter: 6100mm

Application: Ball mill

On August 22, a set of slewing ring with an outer diameter of 6100mm was exported to Southeast Asia. This set a new record in exporting large diameter slewing ring to Southeast Asia.

-

- Slewing bearings with an outer diameter of 5300mm was exported to Russia

-

Country: Russia

Learn More

Product: Slewing bearing

Outer diameter: 5300mm

Application: Tunnel boring machine

On July 1, a set of slewing bearing with an outer diameter of 5300mm was successfully delivered to Russia, which refreshed a record in exporting large diameter slewing bearings to Eastern Europe and Central Asia. This slewing bearing features 7 grades of gear accuracy and 5300mm outer diameter, which was specially designed and manufactured for use in the tunnel boring machines with 10m in diameter.

-

- Case 9

-

Country: United States

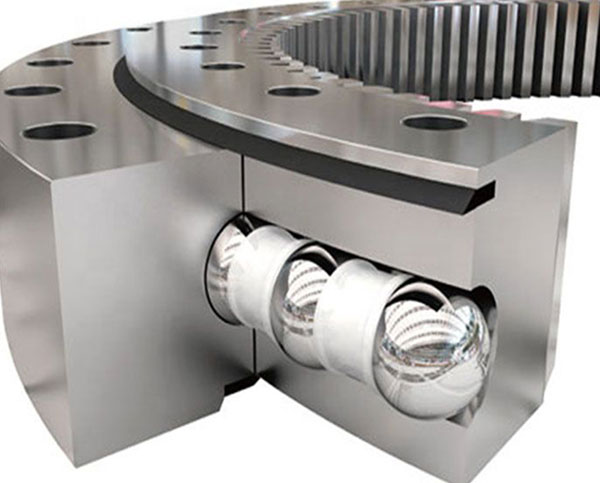

Product: Single-row four-point contact ball slewing bearing (external tooth)

Outer diameter: 4500 mm

Application: Amusement equipment

To ensure that our bearings meet the highest safety standards, we carefully calculate the safety factor for each and every product we produce. As we begin a new year, we want to extend our warmest wishes to all of our customers. We hope that your year is filled with good luck, happiness, and success. And we look forward to continuing to provide you with the highest quality bearing cases for all of your needs.

-

- Case 10

-

Country: United Kingdom

Product: Custom slew bearing (Toothless)

Outer diameter: 11,000mm

Application: Power plant excavator

Custom segmented slew bearing with a diameter of 11 meters, shipping straight to UK customers.

During a gorgeous summer, one of our old customers asked if we could produce bearings with a diameter of 11 meters. Back then, our maximum outer diameter of bearing products was 9 meters.But we didn’t shy away from tough requests. After a meeting with our engineers, researching various measures such as the safety factor, bearing capacity, and overturning moment, we concluded that it’s possible to customize the gear ring, steel ball, and cage. Ultimately, we accomplished the job and fully satisfied our customer's trust. This was a momentous occasion that allowed us to break the boundaries of large bearing capabilities.

Segmented bearing refers to the parts produced by special process design on the basis of integral bearing. With low rotating resistance, stability of operation and a maximum temperature of 180℃, segmented bearing are suitable for operations with low speed, heavy load, strong impact and poor sealing. The primary benefit of using this type of bearing is its easy installation and removal, which saves considerable time and money. As large and heavy rotating shafts fail to meet the required processing and transportation standards, the extensive use of heavy large segmented bearings is becoming more widespread.

-

- Case 11

-

Country: Brazil

Product: Single-row four-point ball slew

Outer diameter: 1800 mm

Application: Excavator

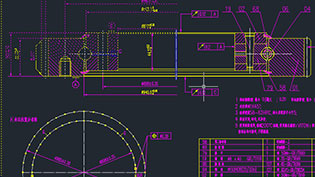

The customer contacted us because the outer ring of their bearing gear had worn out badly. To create an accurate replacement, it is crucial to have precise dimensions and technical drawings. However, the customer did not have these available, which made the manufacturing process a difficult task.To help the customer, we provided a video technical training to assist with measuring the necessary dimensions. After several back-and-forths, we succeeded in recreating the drawings in a month using our specialized knowledge and experience. Once the customer approved the drawings, we immediately began production and worked quickly to complete the order in just 20 days to meet their urgent needs. Despite the challenges, thanks to the trust and support of our customer, the whole project went off without a hitch.

-

- Case 12

-

Country: Russia

Product: Swing Drive SE25

Bearing outer diameter: 868 mm

Application: Automatic welding equipment

Recently, a customer approached us with their own motor and requested that we adapt the input shaft diameter and flange connection diameter of our swing drive accordingly. To ensure a perfect fit, the customer provided us with their drawings and 3D model of the gearbox, and we created appropriate SE25 drawings for their approval.However, during the drawing review process, the customer noticed that the requested transmission ratio was 150:1 while our drawing showed 104:1. We quickly addressed the issue by redesigning the drawing and customizing the rotary drive with the correct transmission ratio of 150:1. Our team ensured that the customer's needs were met before we proceeded with arranging production.

-

- Case 13

-

Country: Singapore

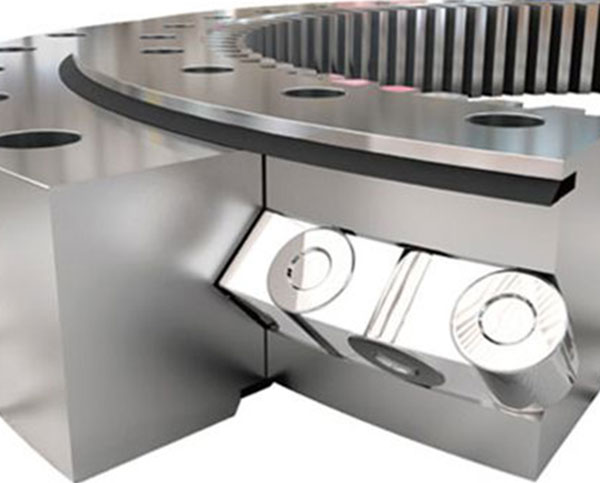

Product: Three-row roller slewing bearing.

Outer diameter: 2850mm

Application: Port machinery crane

Recently, a customer approached us for their new project which required the use of a slewing bearing. After understanding their needs for outer diameter, bearing capacity, and working environment, we recommended a three-row roller slewing bearing that met their requirements.As the slewing bearing was non-standard, our team of experts designed a customized solution to ensure the customer's needs were met. We drew up a design and calculated the load curve based on the customer's requirement for a slewing center of 2625 mm. Our experienced engineers conducted thorough tests and simulations to ensure the final product would be reliable and efficient for the customer's usage requirements.

-

- Case 14

-

Country: United States

Product: Precision bearing (cross roller bearing)

Outer diameter: 150 mm

Application: CNC rotating equipment

A customer approached us with a request for a bearing with an outer diameter of 150 mm, an inner diameter of 76 mm, and a precision grade of P4. Initially, we proposed our standard RU series bearings to the customer, but we discovered that the bearing's height exceeded the size limitations.To provide the customer with the optimal solution, our team of experts worked on modifying the design, offering a high-precision, thin bearing that met the customer's requirements. Our modified design was well-received upon review, and it resulted in a successful collaboration between the customer.

-

- Case 15

- Customer’s country: Germany

- Product: ABS certified three-row roller slewing bearing (Model: 133.50.3550)

- The customer purchased the slewing bearing for marine usage. LYJW provided slewing bearings with long service life, high load carrying capability and high precision to meet the customer’s requirements. The customer was very satisfied with our slewing bearings and ordered six set of same bearings.

-

- Case 16

- Customer’s country: Czech

- Product: slewing bearing for mining machinery

- In May 2016, LYJW manufactured and offered qualified slewing bearings according to the drawing the customer provided. The outstanding quality of our bearings deeply impressed the customer and we have kept the cooperation relationship since then.

-

- Case 17

- Customer’s country: Peru

- Product: custom bearings for bucket wheel excavator

- In 2017, the customer’s original bearing was badly damaged and needed a new bearing. LYJW provided custom bearings for their bucket wheel excavator, which featured compact construction, light weight, high precision, and small installation clearance. By virtue of reliable bearing quality, we have reached a long-term partnership with the customer.

-

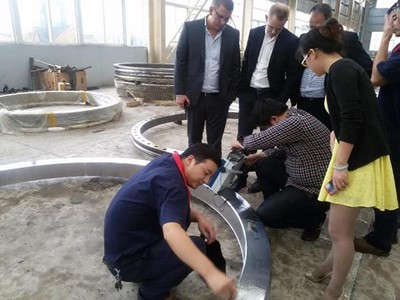

- Case 18

- Customer’s country: Sweden

- The Swedish customer made a field visit to LYJW to further understand our strengths. The customer spoke highly of our work environment, manufacturing strengths, product quality and strict quality control procedures.

-

Custom Bearings

MoreOur dedicated team is on hand to provide help and expertise throughout the process. Whether you are ordering from our standard range of products or you want a tailored solution for your current project, they are ready to help you every step of the way.

-

Manufacturing Process

MoreAfter rough turning, the workpiece is detected by an ultrasonic flaw detector to examine cracks or other flaws and ensure the bearing’s stable quality and normal service life. Quenching and tempering can be conducted according to the requirements, to improve the strength and fatigue resistance of the material.

-

Quality Certificates

MoreTo ensure consistent quality control, we have applied a series of specific and strict measures across all areas of our company. As a high-tech enterprise, our products have passed ISO9001-2000 quality system certification, CCS, ABS, BV, GL and other certifications, and have obtained a number of patent certificates.

-

Services

MoreWe offer both standard and custom bearings tailored to our customers’ specific requirements. After a thorough examination of the bearing condition, size, bearing tooth parameters and any other special processes prescribed by the customer, we will then recommend the most suitable model. To ensure the customer's satisfaction, we also provide detailed diagrams, three-dimensional drawings, and load curves to confirm.