External Diameter: 11,304 mm

Weight: 9,200 kg

Material: 42CrMo castings

Application: Mining equipment

Country: South Africa

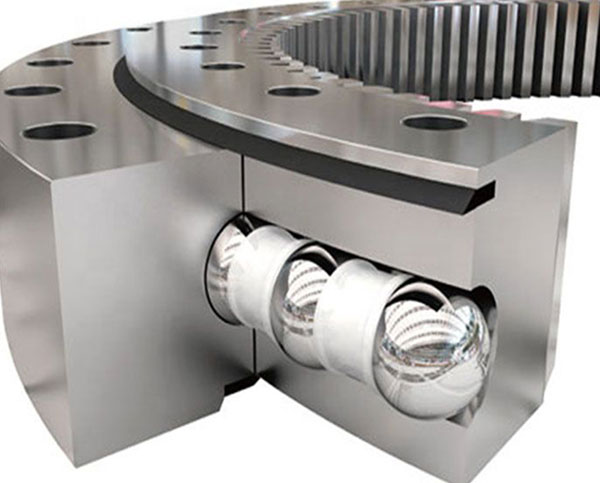

Split gear rings are important components in mining equipment, especially in heavy-duty machinery like crushers and mills. For this particular project, the South Africa client required a large gear ring with an outer diameter of 11,304mm.

Since this size exceeded standard container dimensions, we designed it to be segmented into 8 parts. Made from high-strength 42CrMo castings and heat-treated for durability, the split gear ring is engineered to withstand the heavy loads and impacts encountered in mining operations.

-

Custom Bearings

MoreOur dedicated team is on hand to provide help and expertise throughout the process. Whether you are ordering from our standard range of products or you want a tailored solution for your current project, they are ready to help you every step of the way.

-

Manufacturing Process

MoreAfter rough turning, the workpiece is detected by an ultrasonic flaw detector to examine cracks or other flaws and ensure the bearing’s stable quality and normal service life. Quenching and tempering can be conducted according to the requirements, to improve the strength and fatigue resistance of the material.

-

Quality Certificates

MoreTo ensure consistent quality control, we have applied a series of specific and strict measures across all areas of our company. As a high-tech enterprise, our products have passed ISO9001-2000 quality system certification, CCS, ABS, BV, GL and other certifications, and have obtained a number of patent certificates.

-

Services

MoreWe offer both standard and custom bearings tailored to our customers’ specific requirements. After a thorough examination of the bearing condition, size, bearing tooth parameters and any other special processes prescribed by the customer, we will then recommend the most suitable model. To ensure the customer's satisfaction, we also provide detailed diagrams, three-dimensional drawings, and load curves to confirm.