Thin Section Ball Bearing

- Outer diameter: 63.5mm~317.5mm

- Bore diameter: 50.8mm~304.8mm

- Rated load: 1650N~41340N

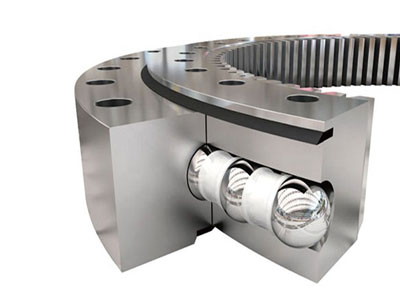

Thin section ball bearings are often referred as constant section bearings, and angular contact is one of the mostly used configurations (also including deep grove radial contact and four-point contact). Angular contact ball bearing features a circular pocket separator and its inner or outer ring is counter-bored to reduce one shoulder of the raceway to form the angular contact.

Its assembly method permits the use of a greater complement of balls and maintains a larger contact angle, making this type bearing can sustain greater axial loads. It can sustain axial load and unidirectional thrust capability, so this bearing should be used together with another bearing.

The chief advantage of angular contact ball bearing is that it offers greater axial load resisting capacity than a deep groove radial ball bearing or four-point contact radial bearing.

The difference between deep groove ball bearing is that angular contact ball bearing has sufficient diametral clearance to produce a substantial contact angle for resisting axial load. The standard thin wall angular contact ball bearing features a constant angle of 30°and approximately 65% of a full complement of balls.

Tags

LYJW is a professional manufacturer of slewing bearings and we can design and manufacture slew ring bearings, precision bearings, slew drives and custom bearings for construction, engineering, mining, marine, chemical, military, wind turbine, medical equipment, and many other industries.

By virtue of expertise team, advanced manufacturing technologies and strict quality management system, LYJW takes the lead in the R&D of slewing bearings, which are designed with reasonable construction, light weight, good load carrying capacity and high versatility. The bearings’ diameters range from 200 to 15000mm and the accuracy covers PO, P6 and P5 class. Now, we can manufacture CCS, ABS, BV, GL and other certified bearings.

We adhere to the business principle of “Quality and Integrity” and we’ll keep providing outstanding bearings and superior services to serve global customer.