Country: Southeast Asia

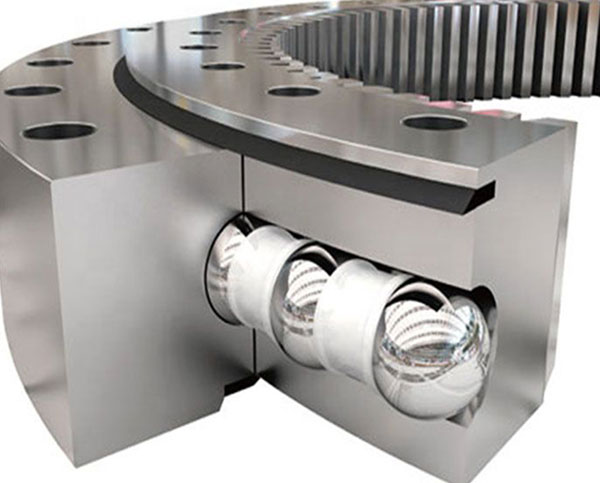

Product: Slewing ring

Outer diameter: 6100mm

Application: Ball mill

On August 22, a set of slewing ring with an outer diameter of 6100mm was exported to Southeast Asia. This set a new record in exporting large diameter slewing ring to Southeast Asia. Due to its large diameter, the ring gear needs to be manufactured in 2 segments for convenient delivery, which brought us higher difficulty in achieving this requirement. After more than 90 days’ manufacturing, the slewing ring with large diameter was ready for timely delivery. We are very appreciated our customer to highly trust our company. We promise to do our best in customer services!

LYJW has more than 10 years of experience in the R&D and manufacturing of ultra-large slewing rings. With strong capabilities, we are striving for leading the industry of large diameter slewing bearings in terms of design, R&D, manufacturing, inspection, etc. In order to better meet international markets’ requirements, we continuously focus on the R&D of new types of slewing bearings for use in high demanding applications.

-

Custom Bearings

MoreOur dedicated team is on hand to provide help and expertise throughout the process. Whether you are ordering from our standard range of products or you want a tailored solution for your current project, they are ready to help you every step of the way.

-

Manufacturing Process

MoreAfter rough turning, the workpiece is detected by an ultrasonic flaw detector to examine cracks or other flaws and ensure the bearing’s stable quality and normal service life. Quenching and tempering can be conducted according to the requirements, to improve the strength and fatigue resistance of the material.

-

Quality Certificates

MoreTo ensure consistent quality control, we have applied a series of specific and strict measures across all areas of our company. As a high-tech enterprise, our products have passed ISO9001-2000 quality system certification, CCS, ABS, BV, GL and other certifications, and have obtained a number of patent certificates.

-

Services

MoreWe offer both standard and custom bearings tailored to our customers’ specific requirements. After a thorough examination of the bearing condition, size, bearing tooth parameters and any other special processes prescribed by the customer, we will then recommend the most suitable model. To ensure the customer's satisfaction, we also provide detailed diagrams, three-dimensional drawings, and load curves to confirm.