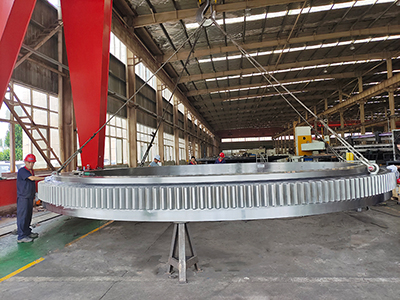

Sold to Southeast Asia

Model: 132.85.7200.03

Outer Diameter: 7897mm

Weight: 47000kg

Application: 1000t harbor gantry cranes

On August 8, our company accomplished the production and testing of large size turntable bearings, and delivered to our client in Southeast Asia. This type of turntable bearing specially designed for use in the harbor gantry cranes is our great achievement, marking another important milestone for the manufacture of key components for heavy machinery and equipment.

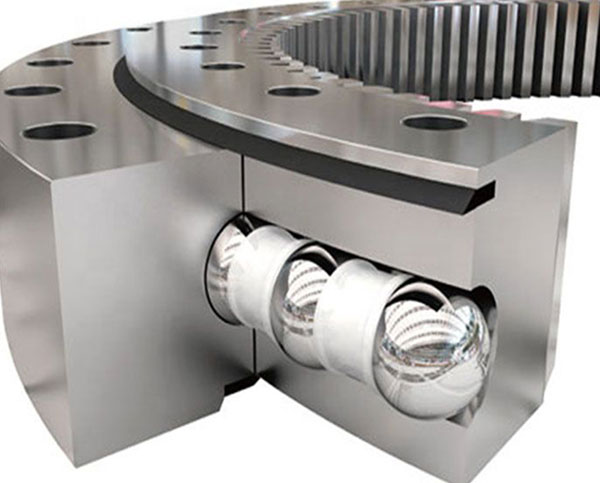

With an astonishing outer diameter of 7,897 mm and a weight of up to 47,000 kg, these slewing ring bearings are huge in size, which requires complicated production process and technology. High-quality materials and advanced technical processes are adopted to ensure the bearings maintain stable operation under extreme conditions, meeting the highest demands on reliability and durability for heavy-duty port equipment.

-

Custom Bearings

MoreOur dedicated team is on hand to provide help and expertise throughout the process. Whether you are ordering from our standard range of products or you want a tailored solution for your current project, they are ready to help you every step of the way.

-

Manufacturing Process

MoreAfter rough turning, the workpiece is detected by an ultrasonic flaw detector to examine cracks or other flaws and ensure the bearing’s stable quality and normal service life. Quenching and tempering can be conducted according to the requirements, to improve the strength and fatigue resistance of the material.

-

Quality Certificates

MoreTo ensure consistent quality control, we have applied a series of specific and strict measures across all areas of our company. As a high-tech enterprise, our products have passed ISO9001-2000 quality system certification, CCS, ABS, BV, GL and other certifications, and have obtained a number of patent certificates.

-

Services

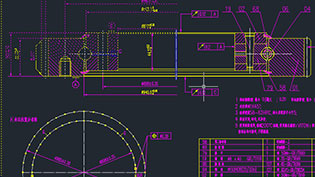

MoreWe offer both standard and custom bearings tailored to our customers’ specific requirements. After a thorough examination of the bearing condition, size, bearing tooth parameters and any other special processes prescribed by the customer, we will then recommend the most suitable model. To ensure the customer's satisfaction, we also provide detailed diagrams, three-dimensional drawings, and load curves to confirm.