Sold to Europa

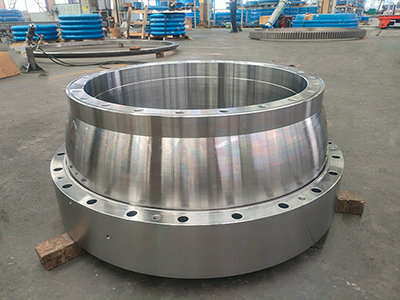

Model: QGJ-0600

Outer Diameter: 1020mm

Weight: 780kg

Application: transmission of tunnel boring machines

The spherical plain bearing is designed for high load carrying capability and long service life under harsh working environments. Adopting this spherical plan bearing greatly improves the working efficiency and operational safety of tunnel boring machines.

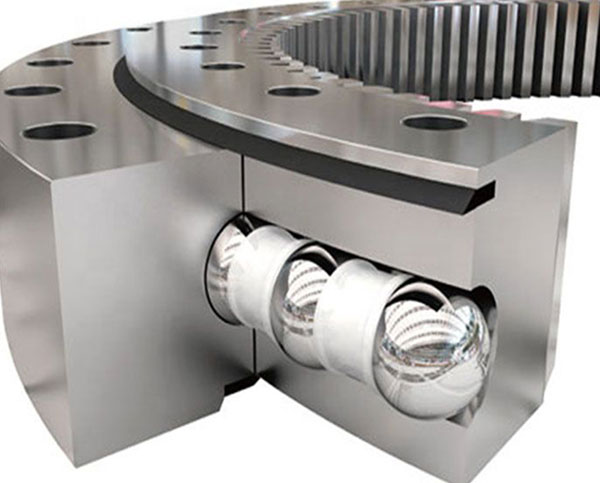

- Strong load accommodation capacity: Designed with different bearing structure, the spherical bearing can accommodate both purely axial loads, radial loads, and combined radial and axial loads.

- Long service life: The bearing is constructed with 42CrMo which undergoes quenching and tempering after rough machining. In addition, it’s processed with surface phosphorification, spray coating, etc. These ensure long service life of the bearing in the demanding environments.

- High-performance materials: High-strength steels and other high-grade alloys are used to ensure the bearing works well under extreme operating conditions.

- Self Lubricating and Easy Maintenance: The spherical plain bearing is composed of an outer ring and an inner ring. Due to the sliding surface, it can freely rotate during movement at any angle. Because the composite material is inlaid on the outer spherical surface of the inner ring, the bearing can produce self-lubrication during operation. This results in ease of maintenance, reduced downtime, and lower maintenance cost.

At present, QGJ-0600 spherical plain bearings have been successfully applied to a number of large-scale tunneling projects, and have been highly praised by users. Luoyang Jiawei will continue to strengthen cooperation with the world's top 500 enterprises, continuously promote technological innovation, and provide better bearings and services for global customers.

-

Custom Bearings

MoreOur dedicated team is on hand to provide help and expertise throughout the process. Whether you are ordering from our standard range of products or you want a tailored solution for your current project, they are ready to help you every step of the way.

-

Manufacturing Process

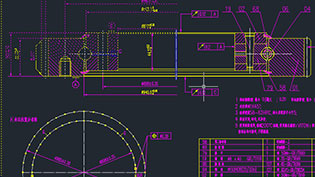

MoreAfter rough turning, the workpiece is detected by an ultrasonic flaw detector to examine cracks or other flaws and ensure the bearing’s stable quality and normal service life. Quenching and tempering can be conducted according to the requirements, to improve the strength and fatigue resistance of the material.

-

Quality Certificates

MoreTo ensure consistent quality control, we have applied a series of specific and strict measures across all areas of our company. As a high-tech enterprise, our products have passed ISO9001-2000 quality system certification, CCS, ABS, BV, GL and other certifications, and have obtained a number of patent certificates.

-

Services

MoreWe offer both standard and custom bearings tailored to our customers’ specific requirements. After a thorough examination of the bearing condition, size, bearing tooth parameters and any other special processes prescribed by the customer, we will then recommend the most suitable model. To ensure the customer's satisfaction, we also provide detailed diagrams, three-dimensional drawings, and load curves to confirm.